Metallurgists have a vital role to play in the path to sustainability. But what is a metallurgist exactly and what do they do?

Metals are crucial to our society. Everything from the smartphone in your hand, to the lighting in your home, to the battery that powers your remote control, requires metals. And we’re growing more dependent on them each day.

For these valuable metals to be useful, though, they first need to be extracted and purified from naturally occurring compounds in the earth’s crust and existing recycled materials.

That’s where a metallurgist comes in.

What do metallurgists do?

Metallurgical engineers design, develop and operate the industrial processes that transform these source materials into the useful materials and manufactured products essential for the functioning of modern society.

Industrial scale metallurgical operations carefully combine physical and chemical separation processes to efficiently extract, refine and recycle metals such as:

- aluminium

- copper

- nickel

- cobalt

- lithium

- gold

- platinum

- rare earth elements.

Types of metallurgists

To define metallurgist, we must consider the 3 main areas within metallurgy:

- mineral processing

- pyrometallurgy

- hydrometallurgy.

Mineral metallurgists physically separate valuable metal components from unwanted components in ores or recycled feed streams.

These metals are then chemically extracted and purified further through processes known as hydrometallurgy (using aqueous solutions to extract metals) or pyrometallurgy (using heat to extract metals in high-temperature processing).

Metallurgists are also involved in the production of advanced materials such as battery components and ceramics.

A metallurgist job description can also include designing new processing plants, overseeing metallurgical operations, and conducting research and development to maintain and improve existing processes and develop new processes.

How are metallurgists helping to save the planet?

Metallurgists have always been crucial to the development of society, from the bronze and iron ages to the modern polymetallic age.

Today, the demand for metals and the way we consume products is changing rapidly. Big societal changes are leading to a critical metals scarcity, which brings new challenges and opportunities for metallurgists. These changes include:

- technological developments in electronic and computer systems

- the move to renewable energy

- the rise of electric vehicles

- the increasing demand for more complex materials.

On top of this, some of the world’s largest companies, including Google and Microsoft, are pledging to use more recycled and renewable materials and reduce landfill. This means we need to design products with reuse and recycling in mind from the beginning, and we need new processes to extract and purify metals from complex recycled materials. Tomorrow’s metallurgists will need to extract critical metals from much more complex sources while also assisting in the development of new materials.

To meet these challenges, the metallurgy industry is going through a period of exciting change. The industry is digitising, and new scientific developments and processes are being developed and implemented.

Metallurgical engineers are currently looking for new ideas and methods for sourcing metals and re-thinking the traditional materials life cycle. They’re also finding new ways of recovering resources from these end products and then putting those materials back into the economy to generate new products. They’re helping to minimise waste, save energy and reduce our carbon footprint.

This sustainable cycle of use is known as the circular economy, and it’s going to revolutionise the way we source metals and build and use everyday products.

Is metallurgy a good career?

Metallurgy is a hands-on field within chemical engineering that’s at the forefront of sustainable engineering.

In fact, there’s never been a more exciting time to be a metallurgist.

While we can’t move away entirely from our need for extracting metals and using them in products, we can do it better. As a metallurgist, you can drive positive change in society by creating the processes that allow us to use and recycle our products and resources carefully and thoughtfully.

The industry is actively seeking fresh ideas and new experts in the field to help move society towards a more sustainable future. This creates a unique opportunity for graduates who have the skills to meet these challenges.

Metallurgist salary Australia

An entry-level metallurgist in Australia with less than 1 year of experience can expect to earn around $82,000 per year, a mid-career metallurgist $120,000 a year, and an experienced metallurgist with 10-19 years of experience, $136,000 a year.

Information sourced from Payscale, Your Career and Labour Market Insights.

Why study metallurgy at UQ?

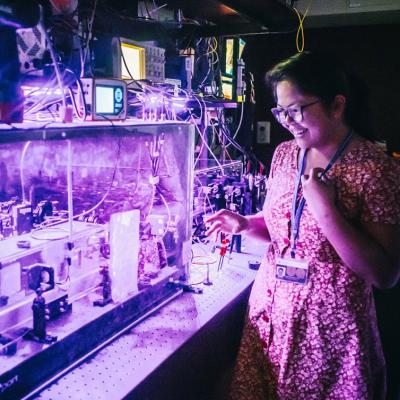

The University of Queensland (UQ) is regarded as one of the best universities in Australia and internationally for studying metallurgical engineering. Our students are gearing up to meet the new challenges facing the industry.

Our graduates are at the forefront of metallurgical education and research thanks to:

- the advanced analytical tools and experimental methodologies they can access here

- new computational and theoretical tools

- the industrial measurement and control opportunities and process innovations we’re developing at UQ, which are being taken up and used by industry.

UQ metallurgy is supported by, and has close links to, the Australian minerals and metallurgical sector and major international companies in the metallurgical, recycling and advanced materials industries.

You can study metallurgical engineering as a major within the Bachelor of Engineering (Honours) program, as part of the chemical engineering specialisation.

The metallurgical engineering major at UQ is unique because of the focus on sustainability and efficiency and the hands-on experience you’ll gain as you complete the program. You’ll deep dive into pyrometallurgy, hydrometallurgy and electrometallurgy. In your second year, you’ll study metal production and recycling, and you’ll get hands-on experience in your fourth year by designing your own metallurgy plant.

Along the way, you can:

- participate in vacation work

- take part in site visits and a metallurgy field trip

- complete a thesis

- get involved in a summer research project.

Meet Isabella, a chemical and metallurgical engineering student at UQ

Looking to join a thriving industry? Want to master metals, help to shape the future and contribute to a better world? Learn more about the metallurgical engineering major within the Bachelor of Engineering (Honours) today.